The paper cup production line contains many paper cup processing machines for producing disposable paper cups. BD paper cup machine manufacturer provides different solutions for manufacturers of different sizes. Our company’s machines can be used to produce paper cups with regular specifications such as 2-32 ounces. And we provide customized solutions. If you want to produce paper cups of other specifications, please let us know.

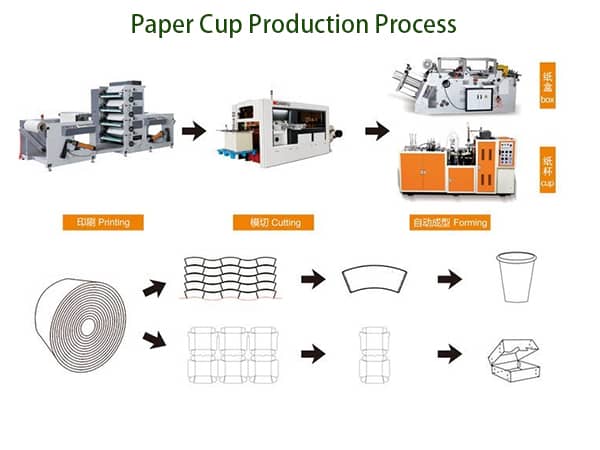

Paper Cup Production Line Process

Paper cup production line process: Purchase PE coated paper—segmentation–sample layout design—printing—cutting—forming –packaging

- PE coated paper: The raw material for the production of paper cups is PE coated paper. It contains two types: single PE coated paper (for ordinary quilts and hot drink cups) and double PE coated paper (for cold drink cups).

- Segmentation & sample layout design: First of all, the width of the paper needs to be determined, which depends on the printing template and the method. Either die cutting or dividing, the following is printing.

- Printing: Print the company logo or other patterns you like on one side of the paper.

- Die cutting: Cut the entire printed paper into fan-shaped paper strips.

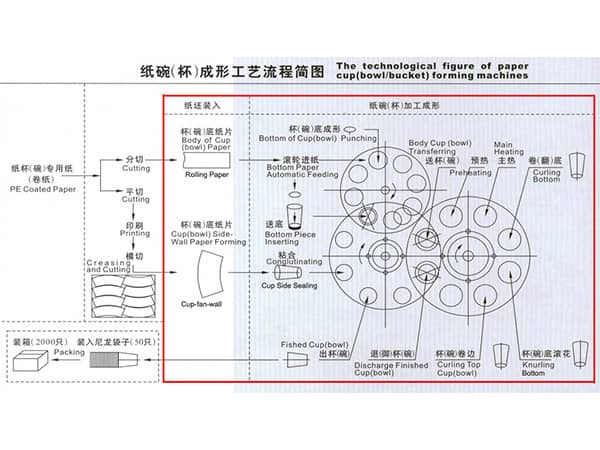

- Forming: Place the paper used to make the cup body and cup bottom on the forming machine to form automatically.

- Packaging: Collect the formed paper cups uniformly and package them for storage.

Automatic Disposable Paper Cup Production Machine

Coated Paper Printing Machine

The coated paper printing machine uses water-based ink to print on paper first.It can greatly improve the printing quality and perform large-format, multi-color color printing. The equipment has high production efficiency and is suitable for long-run mass production.

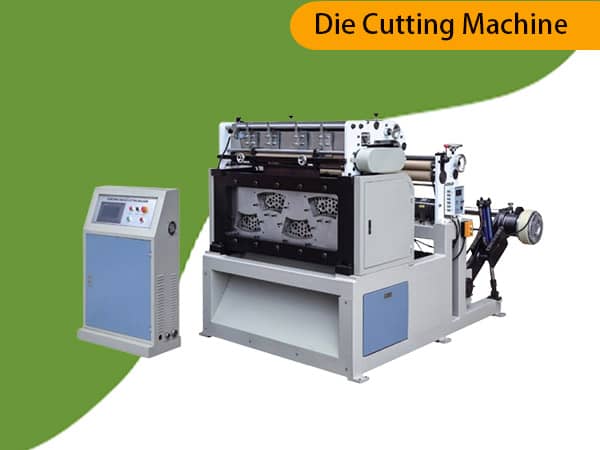

Die Cutting Machine

BD provides two die-cutting machines in the paper cup production line for die-cutting the entire roll of PE coated paper into fan-shaped sheets. The two types of die cutting machines are web die cutting and web creasing die cutting.

The web die-cutting machine is mainly used to die-cut web paper, which is fast and can directly separate the paper and waste materials after cutting. It is suitable for customers with small items and large quantities.

The roll creasing die-cutting machine also uses roll paper, but the film and waste need to be manually separated after die-cutting. It suits customers in a variety of sizes and styles.

Paper Cup Forming Machine

BD paper cup making machine manufacturer provides high, medium and low speed paper cup machines. They can meet the needs of large, medium and small paper cup production factories.

The production speed of low-speed paper cup machine is 70-90cups/min. The production speed of medium-speed paper cup machine is 90-120cups/min. The production speed of high-speed paper cup machine is 120-150cups/min. The automatic paper cup forming machine has the advantages of high performance, high efficiency and high quality.

Paper Cup Packaging Machine

The formed paper cup packaging can be packaged manually or by machine. Using modern intelligent machine packaging, paper cups can be packaged into ordinary single-row or double-row bagging or heat shrinkable film packaging.

Suggestions For Different Paper Cup Production Factories

For a small or just starting paper cup production factory, you can just buy a paper cup forming machine. Then buy printed and die-cut PE coated paper in the market. Then place the purchased fan-shaped pieces and cup bottom pieces on the molding machine for molding.

For medium-sized paper cup factories, you can purchase printing machines and die-cutting machines according to your budget. Then purchase a paper cup forming machine and packaging machine for production.

For large paper cup factories, you have enough space and budget to purchase equipment for production. You can purchase a complete paper cup production line to complete large-scale, automated, high-volume paper cup production.

Advantages Of Paper Cup Production Line

- High degree of automation: Using advanced automation technology, it can realize automatic feeding, forming, trimming, creasing and other processes, greatly improving production efficiency.

- Low production cost: The paper cup production line has a high degree of automation and low labor costs in the production process. At the same time, the cost of paper is relatively low, so the production cost of paper cups is low.

- Environmental protection and energy saving: Paper cups are a recyclable and environmentally friendly product. Paper cups, on the other hand, use less energy during production and produce less waste.

- High versatility: The paper cup machine can produce paper cups of different specifications and shapes to meet the needs of different customers.

- Flexible configuration: BD provides a variety of different paper cup production equipment to meet the production needs of different customers. And we also provide high, medium and low speed molding equipment to supply customers with different budgets and production speed requirements.