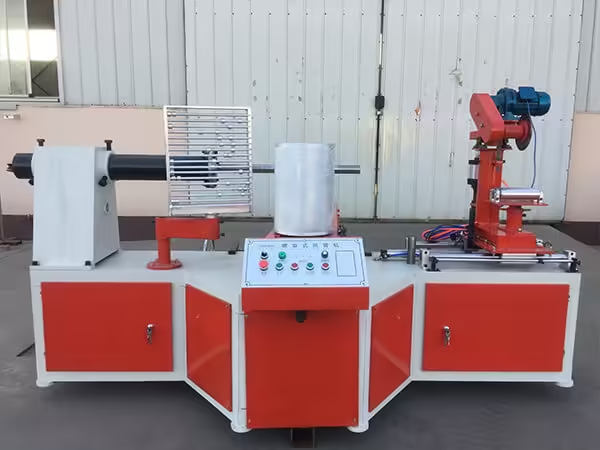

The fully automatic spiral paper tube manufacturing machine uses a spiral winding process to continuously form multiple layers of paper strips into cylindrical paper tubes. The produced paper tubes are used in various industries, including papermaking, printing, food packaging, and construction. The machine is simple yet efficient, capable of meeting the needs of large-scale production.

Spiral Paper Tube Machine Application

The spiral paper tube making machine is widely applicable to paper tubes, packaging tubes, winding tubes, spinning tubes, industrial tubes, etc.

1. Textile Industry: It can be used for winding and transporting textiles, protecting the integrity and quality of the textiles.

2. Chemical Industry: It can be used for packaging and transporting chemical products, ensuring product safety and stability.

3. Construction Industry: The machine can be used for packaging and transporting building materials, improving product protection and convenience.

4. Electronics Industry: The equipment is used for packaging and transporting electronic products, protecting the product’s integrity and moisture resistance.

Structure of a Paper Tube Manufacturing Machine

01. Cutting System: Automatic fixed-length cutting with circular blades, noiseless operation, equipped with an automatic tube drop rack to reduce labor intensity.

02. Glue Testing System: Utilizes domestically leading technology, double-sided glue application, and equipped with a tensioning device, resulting in high-strength finished paper tubes and simple operation for workers.

03. Paper Feeding System: Employs an LZ-type paper feeder with a large paper diameter for convenient paper connection. Equipped with an overhead crane for automatic paper feeding, reducing labor intensity.

04. Transmission System: Main machine with a steel plate frame and bevel gear drive, ensuring high stability and stable, reliable rotation speed.

Advantages of the Automatic Paper Core Making Machine:

1. Supports inner diameters from 15mm to 120mm.

2. Frequency-controlled servo motor synchronous cutting device.

3. Automatic cutting and tube feeding; automatic stop function when paper is out of stock or interrupted.

4. PLC control, touch screen human-machine interface operation; all parameters can be set on the control panel.

5. Multi-blade cutting of paper tubes, high precision, durable. Circular blade active cutting, smooth cut, burr-free.

7. Mechanical structure; steel structure, stainless steel requires customization.

8. Transmission components are specially designed for low noise, high efficiency, and low maintenance costs.

Spiral Paper Tube Manufacturing Machine Production Steps

The production process of a paper tube manufacturing machine is a continuous, automated assembly line operation. The main production steps include raw material preparation and feeding, spiral winding and forming, heat curing and drying, length cutting, and output.

1. Raw Material Preparation and Gluing

Large rolls of base paper are mounted on a paper unwinding rack. The base paper is first longitudinally cut into multiple paper strips of the required width by a slitting machine.

These paper strips then pass through a gluing device, where pre-mixed glue is evenly applied to one or both sides. The glue amount is precisely controlled by metering rollers.

2. Spiral Winding and Forming (Core Step)

The glued paper strips are conveyed to the forming machine. The machine has a high-speed rotating mandrel whose diameter is the inner diameter of the paper tube.

Guided by precision guide rollers, the paper strips are wound layer by layer onto the rotating mandrel at a constant spiral angle (typically 45°-85°). The edges of each paper strip overlap with adjacent layers, ensuring a seamless tube wall. During the winding process, the equipment applies radial pressure to tightly compact each layer of paper and promote initial adhesion of the adhesive.

3. Heating, Curing, and Drying

The wound, wet paper tubes enter the curing zone. Depending on the type of adhesive used, infrared heating, electric heating, or hot air circulation may be employed to heat the paper tubes, accelerating the evaporation of moisture in the adhesive or the curing of the hot melt adhesive, allowing the paper tubes to quickly gain structural strength.

4. Length Cutting

The fully cured paper tubes form a continuous “long line.” It is synchronously conveyed to an automatic cutting machine. The cutting machine uses a high-speed rotating saw or blade to precisely cut to a preset length (e.g., 60cm, 1.5m), resulting in a smooth, clean cut.

5. Finishing and Output

The cut finished paper tubes are conveyed out for automatic stacking, counting, or packaging.

What About Paper Tube Machine Price?

The price of a paper tube machine is influenced by various factors, such as the machine’s features, precision, production efficiency, and brand. Generally speaking, the more powerful, precise, and efficient the paper tube machine, the higher its price. However, a high price does not necessarily mean high cost-effectiveness. Some small businesses, when initially purchasing paper tube machines, do not need overly complex equipment and can choose a basic model that meets their production needs, thus controlling costs while ensuring normal production.

BTM Paper Tube Manufacturer

BTM paper tube manufacturing machines provide complete equipment for paper tube production, including slitting machines and paper tube cutting machines. We also supply toilet paper manufacturing plants with complete sets of equipment such as toilet paper rewinding machines, toilet paper cutters, and packaging machines. If you are interested in toilet paper equipment, please contact us.