Sesame oil making machine is a hydraulic oil press that uses cold pressing to press oil. It has the characteristics of simple operation, high oil yield, and maintaining the natural flavor of the oil. Therefore, cold pressed sesame oil machine is very popular. BTM introduces sesame oil press to you based on the questions that customers often ask during the purchase process. These include: oil press output, structure, working principle, operation steps, oil yield, etc.

Sesame Cold Pressing Method

When using a hydraulic oil press to press sesame oil, the cold pressing method is used. The cold pressing method refers to the method of pressing oil under an environment below 60 ℃. The cold pressing method can retain the characteristics of the original ecological oil making process to the greatest extent and has pure natural characteristics. The sesame oil obtained has a light color, a light and elegant flavor, and the nutrients are most completely retained.

Sesame Oil Yield

Sesame is a food with relatively high nutritional value, and its oil yield is very high. The oil yield of sesame is generally 45%-63%. That is to say, 1kg of sesame seeds can usually produce about 500-600 ml of sesame oil. Then it takes about 3-4kg of sesame to produce 1L of sesame oil. However, the oil yield of sesame is affected by the variety of sesame, the cultivation environment, the harvest period and the processing method.

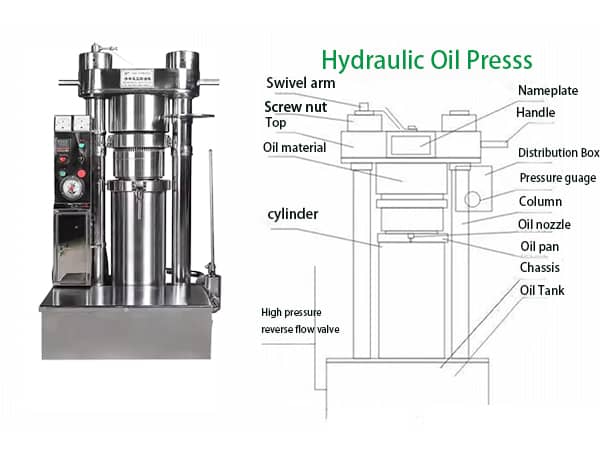

Structure Of Sesame Oil Making Machine

The hydraulic sesame oil making machine is mainly composed of the transmission hydraulic part, the main body part and the hydraulic bidirectional cylinder. The transmission hydraulic part is the heart of the oil press. It converts mechanical energy into hydraulic energy through hydraulic pumps, gear pumps and other components, and then drives the oil press to work. This part uses excellent metal materials to ensure the durability and stability of the seasame oil press. The main body part includes the base, barrel, boring assembly, etc., which is the core area of oil extraction. The hydraulic bidirectional cylinder is the key component to realize the oil extraction action. It realizes high-pressure extraction of oil through the rapid rise and fall of the piston.

Working Principle Of Hydraulic Oil Machine

This new type of hydraulic oil press is an oil extraction equipment that uses liquid as a medium to pressurize the raw material to extract oil. It uses hydraulic oil to transmit pressure through an oil pump. In the downward pressure mode, the motor drives the hydraulic pump to operate, and the hydraulic oil enters the cylinder from the top of the cylinder, thereby pushing the piston downward to press the material. After the pressing is completed, it is adjusted to the upward mode, and the hydraulic oil enters the cylinder from the bottom of the cylinder, pushing the piston upward and returning to its original position. This type of oil press generates less heat during pressing, ensuring that the nutritional components of the oil will not be damaged due to excessive temperature during pressing. It is a true low-temperature physical pressing.

Output Of The Sesame Seed Oil Machine

BTM providessesane seed oil machines with different outputs to meet the needs of different scales of production. From 6YZ-150 to 6YZ-320, the processing capacity ranges from 15kg/h to 350kg/h. The pressing time is also based on the type and quantity of oil, about 6 to 8 minutes. These parameters ensure the high efficiency of the oil pressing process, while also reducing the waiting time for oil and increasing the overall production speed.

Advantages Of Sesame Oil Press Machine

- Low-speed operation ensures full pressing of oil, the oil pressure is large enough to cope with various high-oil crops, and high temperature resistance makes the oil pressing process more stable.

- Simple operation, only need to put sesame into the equipment, and then turn on the machine to squeeze out the oil. It not only reduces the labor intensity, but also greatly improves production efficiency.

- The low-temperature pressing technology is adopted to retain most of the nutrients in the oil. The sesame oil produced is bright in color and pure in taste, which is deeply loved by consumers.

- Low-speed pressing causes little damage to the oil and has a high oil yield. At the same time, it also reduces the generation of oil residue, which is beneficial to environmental protection and resource recycling.

- Fewer replacements of wearing parts greatly reduce the workload and cost of maintenance.

Operation Steps Of Hydraulic Oil Press

- Before starting the machine, you need to ensure that the inside of the oil tank is clean and the hydraulic oil is filled. At the same time, check whether the bolts of each part of the pump body are tightened and whether the circuit connection is correct to ensure that the equipment is in the best working condition.

- Preheating is a step that cannot be ignored before oil pressing. Depending on the season, the preheating temperature should be controlled between 50℃ and 90℃.

- After preheating, open the top plate to prepare for oil pressing.

- When pressing oil, put the fried oil into the press after exhausting the oil smoke. Pay attention to keep the right amount of oil in the press to avoid too much or too little affecting the oil pressing effect.

- Place a cushion on the upper end of the oil in the press, place the partition plate on the upper plane of the press and push it into the press.

- During the oil pressing process, someone needs to operate and read the pressure gauge. When the pressure gauge reaches 55 MPa, the main motor stops working and the oil pressing process is completed. At this time, you need to turn off the power and wait for the pressure of the press to drop. When there is no oil seepage from the oil-pressing seam, it means that the oil has been squeezed out and the next cleaning work can be carried out.

- When cleaning, first open the top plate, take out the oil cake, and then lower the piston to the bottom to prepare for the next round of oil pressing.

It should be noted that during the entire operation, the operating procedures must be strictly followed to ensure safety. Especially under high pressure, unrelated personnel are strictly prohibited from approaching the equipment to avoid danger.

Maintenance And Care Of Sesame Oil Making Machine

- The maintenance of sesame oil extraction machine is the key to ensure its long-term stable operation. Daily maintenance should include checking the hydraulic oil level to ensure that the oil level is within the normal range. At the same time, check whether the bolts of each part are tightened and whether there is any looseness. Regularly check the pipes and joints of the hydraulic system to ensure that there is no oil leakage.

- In addition to daily maintenance, the hydraulic oil press also requires special treatment when it is parked for a long time.

- When not in use for a long time, the equipment should be stored in a dry and ventilated place to avoid moisture and corrosion.

- The hydraulic cylinder should be moved regularly to prevent the seal from being compressed and deformed for a long time.

- The electrical part should be waterproof and dustproof to ensure insulation performance.

- In addition, after long-term parking, the motor insulation should be checked before using again to ensure safety.

- Through regular maintenance, the service life of the hydraulic oil press can be extended, the failure rate can be reduced, and production efficiency can be improved. Users should develop the habit of regular inspection and maintenance to ensure that the equipment is always in the best working condition.

Common Problems And Solutions

During the use of hydraulic sesame oil press, users may encounter some problems. Here are some common problems and their answers:

The lack of oil may be due to insufficient oil in the press bore or insufficient pressure in the hydraulic system. Check the oil volume and hydraulic oil level to ensure that they are within the normal range.

First check whether the pressure gauge is damaged. If damaged, replace it immediately. Check the electrical control system to ensure that the circuit is connected correctly.

The heating of the oil may be due to too long oil pressing time or too much oil in the press bore. Properly adjust the oil pressing time and oil amount to ensure the oil pressing efficiency.

In addition to the above problems, users should remember not to leave the equipment when using the oil press to prevent emergencies. After the oil is pressed, the equipment should be cleaned in time to keep it clean and hygienic. In addition, the equipment needs to be lubricated and maintained regularly to prevent parts from wearing out.