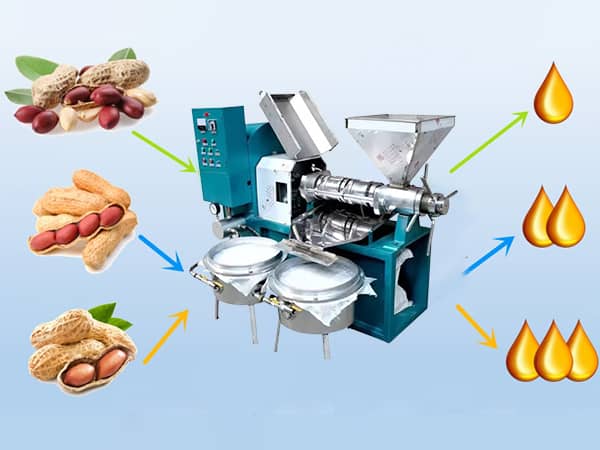

The peanut oil extraction machine is a device that uses a screw press to separate the oil from peanut kernels. This equipment is widely used in households, small oil mills and commercial oil mills. It can meet the needs of household use and can also be used for large-scale production. When buying a peanut oil making machine, many customers usually want to know about how peanut oil is squeezed out, how much is the output, how is the oil yield, how is the peanut oil extraction business, and whether it is profitable. BTM peanut oil extraction machine manufacturer will introduce you to the peanut oil extraction machine from the above aspects.

Output Of Peanut Oil Making Machine

BTM provides machine models with screw diameters ranging from Ф55 to Ф125. The smallest output is 40-60kg/h, and the largest output is 300-350kg/h. Therefore, you can choose BTM’s peanut oil press for your family, small oil mill and commercial oil mill. For specific models, please check the parameters of screw oil press.

Peanut Oil Yield

The oil yield of peanuts is usually between 40% and 53%. The specific oil yield is affected by the peanut variety, oil content, moisture content, and the performance and operating conditions of the oil press. For example, hot pressing usually has a higher oil yield than cold pressing. But cold pressing can better preserve the nutrients of peanut oil. If you want a higher oil yield, it is recommended to use hot pressing – heating the peanuts before pressing.

Peanut Oil Extraction Steps

- Raw material pretreatment: Peanut raw materials need to be cleaned, shelled and dried first to ensure that the moisture content is about 8.5%.

- Feeding: Pour the pretreated peanuts into the hopper and evenly feed them into the pressing chamber through the feeding system.

- Pressing: The pressing screw of the oil press pushes and squeezes the peanuts to extract the oil. As the space in the pressing chamber gradually becomes smaller and the pressure increases, the oil in the peanuts is squeezed out.

- Oil discharge and slag removal: The squeezed oil flows out through the gap of the pressing cage, and the oil residue is pressed into a cake and discharged.

- Filtration and refining: Equipped with vacuum oil filter to filter impurities in the squeezed crude oil.

Configuration Of Peanut Oil Making Machine

Added automatic control functions for seed frying and chamber heating. It changed the traditional way of heating the dried cake, shortened the preparation time. Reduced energy consumption and machine wear, and extended the service life of the oil making machine.

Adopted multi-stage pressurization and vacuum filtration system to improve oil pressing efficiency and oil quality.

Adopted multi-stage pressing, directional pressing, high-quality steel for the screw. Integrated with advanced technology, pressure-free continuous high-temperature continuous operation, high pressing efficiency.

Peanut Oil Pressing Business Is Profitable

Some customers want to know whether the peanut oil pressing business is profitable. Below, BTM oil press manufacturer takes a medium-sized oil press (80-120kg/h) as an example for analysis.

Basic assumptions

Processing capacity: 100kg/h peanuts.

Oil output rate 45% (actual oil output rate varies depending on equipment and raw material quality)

Working hours: 8h/day.

Cost Calculation

| Item | Unit | Unit(RMB) | Cost per hour (RMB) | Cost Per Day(RMB) |

| Peanut raw material | Kilogram | 12 | 1200 | 9600 |

| Electricity cost | degree | 1.2 | 10.8(Assuming 9 kWh of electricity consumption per hour) | 86.4 |

| Equipment depreciation | year | 10000(equipment cost)/365day/8hours | 3.42 | 27.36 |

| Maintenance costs | day | 5 | 5 | 40 |

| Other costs | day | 10 | 10 | 80 |

| Total cost | 1255.8 | 10087.36 |

Profit Calculation

| Item | Unit | Unit(RMB) | Hourly income (RMB) | Daily income (RMB) |

| Peanut oil | Kilogram | 25 | 1125(45KG oil) | 9000 |

| Peanut biscuits (by-product) | Kilogram | 3 | 165(55KG oil biscuit) | 1320 |

| Total revenue | 1290 | 10320 |

Based on the above assumptions, the profit per hour is about 34.2 RMB,the profit per day is about 232.64 RMB. It should be noted that the actual profit may vary due to factors such as fluctuations in raw material prices, differences in equipment performance, and changes in market demand. In addition, if the production scale is expanded or the operation process is optimized, costs may be further reduced and profits may be increased. Therefore, the peanut oil pressing business is profitable.

Structure of Peanut oil press machine

The main structure of Peanut oil press machine includes the following parts:

- Hopper: The peanuts enter the interior of the peanut oil press through the funnel, and the funnel design allows the raw materials to be fed evenly.

- Pressing chamber:It is the part where oil is pressed. It is equipped with a pressing screw or hydraulic device inside to squeeze the oil in the peanuts through mechanical force.

- Pressing screw: This is a key component in oil extraction. The screw thread design and rotary motion continuously push and squeeze the peanuts to extract the oil from the peanuts.

- Cake adjustment device: The adjustable cake gap at the end controls the pressing force.

- Filtering device: used to filter the squeezed oil, remove impurities, and ensure the purity of the oil.

- Heating device:It equips with a heating function to improve the oil pressing efficiency and oil output rate by controlling the temperature.

- Frame: The structure that supports the entire equipment to ensure the stability of the equipment during operation.

What Is The Peanut Oil Machine Price?

Many customers usually consider the price of peanut oil press when purchasing it. BTM tells you that the price of oil press is mainly affected by output, function and configuration. The greater the output, the more complete the function, the more configuration, the more expensive the machine. In general, the peanut oil machine price is usually between 6000-70000 RMB. For the specific price, please consult the BTM oil press manufacturer.