The screw mustard seed oil machine is an ideal choice for mustard seed oil processing. It occupies an important position with its unique process advantages and high processing output. Mustard seed oil is rich in monounsaturated fatty acids, has a neutral flavor and good nutritional content, so it has become more and more popular with customers in recent years. Therefore, the sales of mustard seed oil extraction machine are also gradually increasing. The screw and hydraulic oil presses provided by BTM mustard seed oil press manufacturers are also used for oil extraction of oil crops such as peanuts, soybeans, almonds, walnuts, sunflower seeds, coconuts, etc.

Global Rapeseed Market Overview

According to Verified Market Reports, the market areas for mustard seed oil extraction are mainly concentrated in North America, Asia Pacific, Europe and other regions. In 2023, the market share of mustard seed oil extraction in North America was 35%, in the Asia-Pacific region 30%, and in Europe 20%. The extracted mustard seed oil can be used not only in the food industry, but also in cosmetics, biofuels, industry and other fields.

Commercial Mustard Seed Oil Machine Introduction

There are two types of oil press machine for extract mustard seed oil: screw and hydraulic.

Screw oil press has become the mainstream choice due to its continuous production capacity and high oil yield, especially suitable for oil crops such as mustard seeds with an oil content of 38-40%. Its working principle is based on the screw rotating to push and squeeze the mustard seeds, and the high-intensity pressure squeezes the oil out of the crop.

Hydraulic oil press uses cold oil pressing method. The vertical hydraulic oil press uses a high-low pressure combined plunger pump station, which is particularly suitable for small-scale cold pressing process. Its low-temperature pressing characteristics (≤60℃) can retain more than 90% of vitamin E and unsaturated fatty acids in mustard oil, but the processing capacity is relatively limited.

Screw VS Hydraulic Mustard Seed Oil Extraction Machine

The following is a comparison of the two oil presses for mustard oil extraction process, scale, oil yield, etc. by BTM combined with the characteristics of the two oil presses. You can choose the appropriate equipment for oil pressing according to your production needs.

| Performance indicators | Screw oil press (6YL-100) | Hydraulic oil press (6YZ-230) |

| Processing capacity | 150-230kg/h | 60-120kg/h |

| Residual oil rate | ≤6% | ≤5% |

| Energy consumption | 11.25KW | 2.4KW |

| Suitable scale | Medium and large oil mill | Small oil mills/laboratories |

| Process adaptability | Hot pressing is the main method | Cold pressing is the best |

What Is The Oil Yield Of Mustard Seeds?

The oil yield of mustard seeds is affected by multiple factors such as variety, pretreatment process and equipment performance. According to the data from the Agricultural Planting Network, the oil content of mustard rapeseed is usually between 30-45%, of which double-low rapeseed can reach 40-45%. When the moisture content of mustard seeds is kept at 8-10% and the steaming and frying temperature reaches 120-130℃, the actual oil yield can be stabilized at 38-42% with the multi-stage pressing of the efficient mustard seed oil press, that is, 380-420 ml of mustard oil can be produced per kilogram of mustard seeds.

It is worth noting that different processes have a significant impact on the oil yield. The hot pressing process increases the activity of oil molecules by steaming and frying at high temperatures (120-180℃), which is 8-12% higher than the yield of cold pressed oil, but some heat-sensitive nutrients will be lost.

Input-Output Ratio And Investment Return Analysis

Take a medium-sized oil mill that processes 2 tons of mustard seeds per day as an example. The economic benefit analysis of the BTM-6YY-230 screw oil press is as follows:

Raw material cost: mustard seed purchase price is 4.5 yuan/kg, daily cost is 9,000 yuan

Oil output: calculated at 38% oil output, daily mustard oil output is 760 liters, selling price is 15 yuan per liter, daily income is 11,400 yuan

By-product income: oil cake output is 1,240 kg, selling price is 2 yuan/kg, daily income is 2,480 yuan

Energy consumption cost: total power is 3.2KW, daily power consumption is 76.8 degrees, and electricity bill is about 80 yuan

Daily net profit: 11,400+2,480-9,000-80=4,800 yuan

According to this calculation, the equipment investment (about 150,000 yuan) can be recovered within 3-4 months. The customer case provided by BTM shows that the annual net profit of a small oil mill using a hydraulic oil press can reach 80,000-100,000 yuan, which is particularly suitable for starting a business in townships.

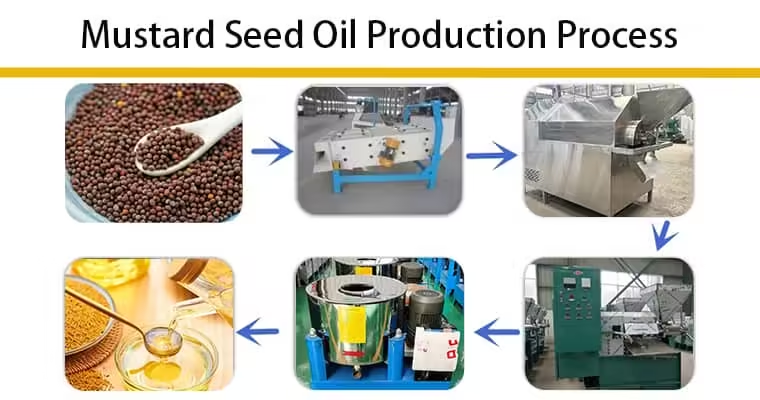

Complete Mustard Seed Oil Pressing Process

The pretreatment process of commercial mustard seed oil pressing directly affects the final oil yield and oil quality, including the following key steps:

Cleaning and impurity removal: manually or using equipment to remove stems, leaves, sand and metal impurities, and the impurity content must be controlled below 0.5%

Moisture adjustment: Use a wok to reduce the moisture in mustard seeds. The moisture content after frying is maintained at 8-12%, and can be appropriately increased to 13% in winter

Steaming and frying: The multi-layer vertical steaming and frying pan is heated by steam to evenly raise the material temperature to 120-130℃, and the time is controlled at 25-30 minutes

Mustard seed oil pressing: Put the mustard seeds into the hopper of the oil press (screw type) and enter the blasting chamber through the hopper. As the screw rotates and moves, the space in the press chamber continually shrinks and the pressure on the material gradually increases, causing the oil to separate from the mustard seeds.

Filter out impurities: The oil squeezed out by the oil press will have some impurities and is not completely pure. Therefore, an oil filter is needed to separate the impurities in the oil. The equipment uses the centrifugal force of the high-speed rotating drum to filter the oil.

Choose BTM Oil Press Machine Manufacturer

BTM is a manufacturer targeting small and medium-sized oil press plants/workshops. We provide single oil press equipment and small and medium-sized oil press production lines. And we provide comprehensive pre-sales, in-sales and after-sales services. BTM promises 24-hour online service to support your product consultation and after-sales service. The core components are guaranteed for one year. During the one-year period, BTM promises to provide free components that are not damaged by human factors. If you want to find an oil press, please contact BTM.